Metal stamping is a way to work with metal that has been done for many years. It involves using multiple stages of compressive deformation to shape different metals into specific parts or shapes. In stamping, an outside force is put on a single work or metal sheet. The metal can be made of different alloys, each of which has its level of malleability.

Stamped metal parts and products that metal stamping suppliers supply can be manufactured from various metal stamping materials that are stronger, last longer, have a better mass-to-performance ratio and work better without changing the weight much.

Importance of Metal Stamping Products Supplied by Metal Stamping Suppliers

Astonishingly Right

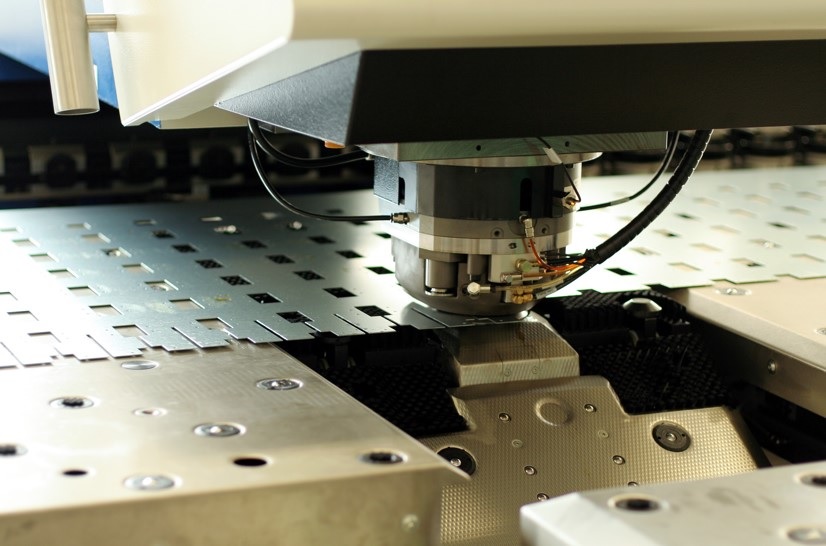

The level of precision, which goes down to the micron level, is the best thing about metal stamping. With the help of new technology, this process is so complex and detailed that it can be used to shape metal into the most complicated shapes. The chance of making a mistake is almost non-existent because sensors and camera systems are used to check the size as the process goes on.

Less Money Wasted

Metal stamping is also suitable for businesses because it is a cost-effective way to make things. It cuts down processing time by a lot and speeds up production at the same time. By making the production process go faster, companies use fewer machines, have fewer workers, and spend less time on work. Because of this, it’s normal for production costs to drop by a lot.

People think that metal stamping helps businesses by making production times more efficient. This efficiency is the best way to cut costs. Metal stamping is an excellent option for companies that need to make a lot of parts at once. A method like this is helpful in electronics, cars, and semiconductors.

So Many Ways to Use It

Metal stamping is prevalent in many industries because it can be used in many ways. It makes it possible to shape metal, which is light but strong, into tiny and complicated shapes. However, sticking to the specs during the process should be easy. When looking for metal stamping suppliers who make things out of metal, make sure they can design, engineer, package, and put something together. There are many ways to use design for a wide range of industries.

It’s not a surprise that the number of implantable parts has grown in recent years. Since clamps, clips, and brackets used in the human body are usually small, pressing has been the best way to make them. Also, metal stamping has become a great way to make surgical tools, which must be made to very tight tolerances.

High Standard

Metal stamping is a well-known way to make parts that are of high quality. Stamped parts have proven to be so reliable that they have been used in complicated procedures like laparoscopic surgery. This method has also been used to make more and more cases for electronic devices.

Also, most of the enclosures of devices are made of titanium, which is known for being resistant to rust and bacterial growth. Since stamping technology has improved, titanium can be stamped just as quickly as steel.

Quality Assurance:

Established metal stamping suppliers prioritize quality assurance throughout the manufacturing process. From material selection to the final inspection, they adhere to stringent quality control measures to guarantee the consistency and reliability of the stamped components. This commitment to quality minimizes the risk of defects and ensures customer satisfaction.

Rapid Prototyping:

In today’s fast-paced market, the ability to bring new products to market quickly is a key competitive advantage. Metal stamping facilitates rapid prototyping, enabling manufacturers to test and refine designs efficiently. The quick turnaround time in metal stamping ensures that design iterations can be implemented promptly, allowing companies to stay ahead in the innovation race.

Versatility in Materials:

Metal stamping is not limited to a specific type of metal. It can be applied to a wide range of materials, including aluminum, stainless steel, copper, and more. This versatility allows manufacturers to choose materials that best suit the desired properties of the final product, whether it be strength, conductivity, or corrosion resistance.

Technological Advancements:

Leading metal stamping suppliers invest in the latest technologies and equipment to stay at the forefront of the industry. This commitment to innovation enables them to offer cutting-edge solutions, such as precision tooling and advanced stamping techniques, to meet the evolving needs of their clients.

Customization Capabilities:

Every manufacturing project comes with unique requirements, and reliable metal stamping suppliers understand the importance of customization. They offer tailored solutions to accommodate specific design specifications, ensuring that the stamped components align perfectly with the intended application.

Conclusion

For different industries, stamping has benefits like high precision, fast production, low secondary costs, and a quick turnaround. It’s a method that should be used by any business that needs precise parts supplied by metal stamping suppliers.